Marshall Jones

"However difficult the path, if you love what you are doing, you’re going to find a way."

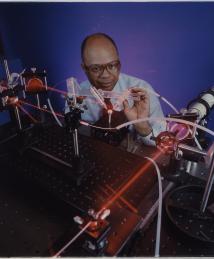

Marshall Jones, a mechanical engineer at General Electric (GE), pioneered the use of lasers for industrial materials processing. He invented novel methods to weld dissimilar metals, and developed fiber optic systems making lasers much more convenient for industrial applications.

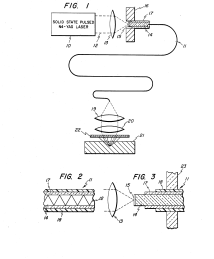

A powerful heat source, lasers can deliver enough light energy to weld and cut metals and plastics. In the mid-70s, Jones invented a technique using a laser to rapidly weld copper and aluminum. He later developed methods to weld other dissimilar metals including molybdenum and tungsten. In 1982, Jones initiated research and development of fiber-optic laser-beam delivery systems resulting in a laser beam powerful enough to cut steel, titanium, and nickel-based alloys, and to weld and drill them at multiple angles. In 1988, Jones and his team developed a laser-welding system using fiber-optic cables to simultaneously split a laser beam and heat opposite sides of a workpiece.

Jones's work revolutionized the method of making lead wires that's used in light bulbs. It is utilized in GE's production of ceramic metal halide lamps, diesel engine head-liner assemblies, control rods for nuclear reactors, and flat emitters for x-ray tubes. Manufacturers including Ford and Lockheed Martin have used products and hardware that resulted from GE's laser based processes.

Jones earned a B.S. from the University of Michigan, and M.S. and Ph.D. degrees from the University of Massachusetts. A member of the National Academy of Engineering, he holds over 50 U.S. patents and 57 foreign patents, and is recognized as one of the foremost authorities in the field of laser material processing.