Iver Anderson

"I really enjoy solving problems. The motivation is especially strong to solve a problem if somebody says it’s not possible."

Iver Anderson invented lead-free solder, a revolutionary tin, silver and copper alternative to traditional tin and lead solder. Anderson's solder has reduced environmental hazards and is a metallurgical advancement that has transformed electronic packaging and been adopted throughout industry for use in manufacturing.

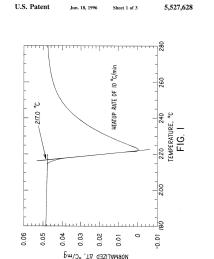

To perform successfully, solder must melt at one temperature, flow easily, then solidify quickly to create a strong, durable bond between metal parts. Late in the 20th century, studies showed that lead in discarded solders leached into landfills and aquifers, threatening human health. Research conducted by Anderson — a professor at Iowa State University and metallurgist at Ames Laboratory — and his team led to the innovative solder. Like the traditional tin-lead alloy, Anderson's tin-silver-copper alloy acts like a pure metal with a single melting point — the key feature of a solder. Today, 70% of electronic items in the world contain Anderson's lead-free solder.

Besides minimizing toxic environmental impacts and manufacturing costs, the solder can withstand greater stress, higher temperatures and temperature changes, more rugged settings, and resist corrosion that can weaken soldered connections — all important to optimal functioning of smartphones, laptops, tablets and similar devices. In addition to typical solder ingot and paste, the solder alloy also can be formed into sheets or wires for accurate placement.

Anderson received his bachelor of science in metallurgical engineering from Michigan Technological University, and master of science and doctoral degrees from the University of Wisconsin-Madison. He is an internationally recognized authority on lead-free solder, and his research includes powder metallurgy, rapid solidification and joining problems. Anderson holds 39 patents.