Maurus Logan

Electrical engineer Maurus Logan invented cable ties to address worker safety and wiring installation inefficiencies in the aviation industry. Now a billion-dollar market segment, cable ties are a fastening solution used in a wide variety of industries and projects, from aerospace to agriculture to DIY home improvement.

Logan was born in 1921 in Dalmuir, Scotland, a small community near Glasgow. His father worked as a boilermaker at several shipyards, the dominant industry in the area. When the family came to the U.S., they eventually settled in Staten Island, New York. Logan graduated from Ralph R. McKee Vocational High School, where he was trained as an electrical draftsman.

Logan had both the mindset and the skills to succeed in his career. His son Robert Logan would later say, “He never thought the customary way of doing things was good enough and when he looked at anything he thought about ways to improve it.” With the education he received at vocational school, he could then take any idea and quickly sketch a prototype.

After working as a drafter for Bethlehem Steel Shipbuilding, and later for the Diehl Electric Motor Division of the Singer Manufacturing Co., Logan joined Thomas & Betts Corp. (now ABB Installation Products) in the early 1950s. This company designed and manufactured connectors and components for electrical and communication markets, and Logan was hired to work on product development. Before creating the cable tie, he developed installation tools, a split-tee connector and insulated compression connectors, which were used extensively in the aircraft industry in the 1950s.

In 1956, Logan visited Boeing Co. to discuss applications for compression connectors, and a delayed flight home to New Jersey left him with extra time to tour an aircraft assembly line. He observed workers constructing airplane wire harnesses by laying out thousands of feet of electrical wiring along 50-foot-long sheets of plywood. They secured the wiring with braided, wax-coated nylon cords, knotting the cords and pulling them tight by wrapping them around their fingers. This often caused cuts and thick calluses, leading workers to develop what became known as “hamburger hands.” Logan knew there had to be an easier, more efficient way to accomplish this critical task. Over the next two years, he experimented with different tools and materials, and he made several trips to production lines to speak directly with workers to better understand their processes.

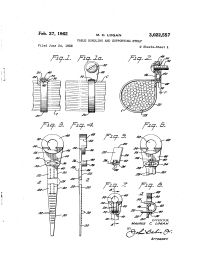

In 1958, Logan filed for a patent on his nylon cable bundling and supporting strap design, which became the Ty-Rap® cable tie. The patent was issued in 1962. The first example of a self-clinching cable tie, Ty-Rap was a flexible, durable and corrosion-proof nylon strip. At one end, it had a hole with teeth, and at the other end were embossed ridges that acted as a ratchet. The stainless-steel locking device in the tie head resisted corrosion and was nonmagnetic. The tie could be wrapped around a bundle of cables or wires, with the ridged end threaded through the hole. When it was pulled tight, the teeth-and-ratchet combination held the tie in place. Its rounded edges prevented it from damaging wiring or cables while also protecting workers’ hands.

Logan's invention required no additional tools or expertise to use. The ties were easy for workers to pick up, even when wearing gloves, and they could be tightened easily, even in wet or cold conditions. Ty-Rap cable ties quickly became popular due to their ease of use, reliability and versatility. Bundling with cable ties is several times faster than tying cables with string, and it reduces the risk of injury to worker's hands, especially if the worker used a special tool Thomas & Betts offered to easily fasten and clip the ties.

Today, Ty-Rap cable ties are used worldwide in an array of applications. They have become essential in industries, including electrical, construction, automotive, consumer goods, packaging, food and beverage processing, healthcare, telecommunications, and transportation.

There are now many varieties of cable ties available, including ties made of specialty materials that are designed to withstand extreme temperatures, high humidity, ultraviolet and other kinds of radiation, aggressive chemicals or even conditions in outer space. For example, NASA has used high-performance polyamide ETFE Ty-Rap cable ties to fasten interior and exterior conduits and components on the Mars Perseverance rover and to support research and lab equipment. Ty-Rap cable ties are also used on the NASA Curiosity rover and were previously used on the Spirit and Opportunity rovers.

The global cable tie industry generated $1.4 billion in 2021 and is estimated to reach $2.6 billion by 2031. Since its invention, more than 30 billion standard and high-performance Ty-Rap brand cable ties have been produced, and billions more have been produced by other manufacturers. ABB currently sells cable ties under a variety of brand names, including Ty-Rap, Ty-Met® (stainless steel), Ty-Fast® (all plastic), Twist-Tail™ and Spec-Kon® cable ties, and manufactures cable ties with metal teeth, as well as all-plastic ties.

Logan retired as vice president of research and development at Thomas & Betts, and he continued to invent throughout his life. Before passing away in 2007, he was working on an improved medicine dispenser as he remained determined to find practical solutions to the challenges of daily life.